Harness the Strategic Edge of Concrete Scanning for Unparalleled Project Success and Quality Control

In the realm of contemporary construction and framework development, the utilization of concrete scanning innovation has actually arised as a critical tool for making sure task success and keeping high quality standards. The true power of concrete scanning exists not only in its capacity to improve job outcomes yet likewise in its capability to revolutionize standard methods, establishing a brand-new criteria for accuracy and effectiveness in the construction industry.

The Importance of Concrete Scanning

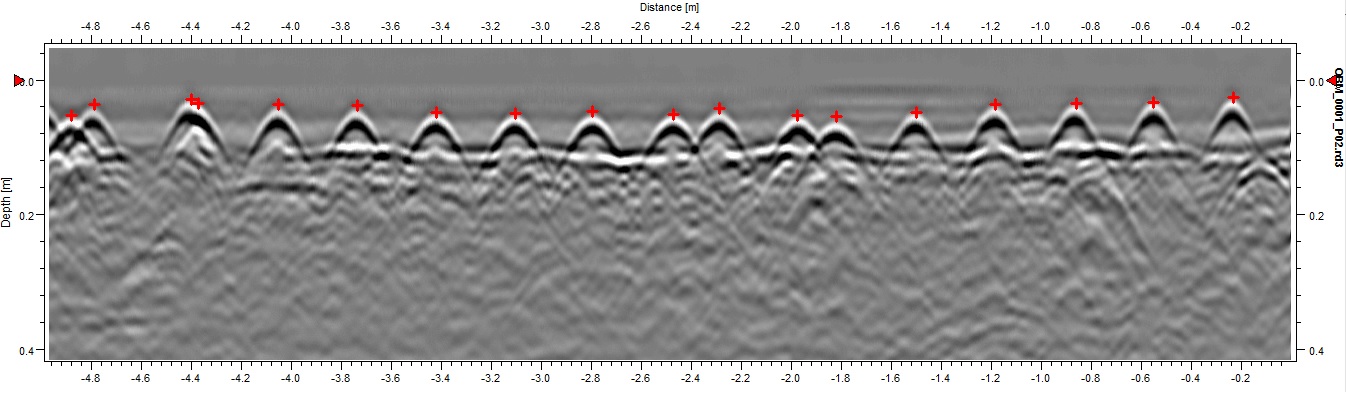

Concrete scanning is a necessary action in building jobs to ensure the security and integrity of frameworks. By making use of numerous scanning innovations such as Ground Passing Through Radar (GPR) and electro-magnetic induction, construction groups can non-destructively evaluate the subsurface of concrete structures to identify potential threats like rebar, channels, or post-tension cable televisions. This details is critical for project designers, managers, and service providers to make enlightened choices and prevent pricey errors throughout the construction process.

Among the key reasons that concrete scanning is so important is its capacity to protect against crashes and injuries on the building and construction site. Inadvertently cutting with an online electric avenue or damaging post-tension cords can have catastrophic repercussions, not just in regards to safety however also in regards to project hold-ups and financial ramifications. By performing extensive concrete scanning before any kind of boring, reducing, or coring activities, building and construction groups can minimize risks and develop a safer working setting for every person involved.

In enhancement to safety factors to consider, concrete scanning also plays a crucial duty in making sure the long-lasting longevity and quality of the framework. By identifying any type of anomalies or flaws concealed below the surface area, such as spaces or delamination, early treatment can be applied to resolve these issues before they rise into even more considerable issues. Inevitably, purchasing concrete scanning is a proactive step that can conserve time, cash, and sources over time, while likewise upholding the greatest requirements of building and construction excellence.

Advanced Innovation for Precise Outcomes

Furthermore, 3D scanning modern technologies provide an extensive sight of the subsurface atmosphere by creating detailed digital designs. These models provide important understandings into the structural integrity of concrete components and help in determining possible weaknesses before they escalate right into major problems. By including these advanced technologies right into concrete scanning techniques, building groups can improve workflows, decrease task delays, and make certain the overall quality and success of the job. The precision and effectiveness offered by these tools contribute significantly to the job's success by assisting in educated decision-making and improving quality control measures.

Enhancing Task Efficiency and Timelines

In addition, concrete scanning allows teams to identify potential dangers and structural weaknesses early, allowing for prompt remediation and protecting against accidents that might thwart task timelines. The real-time data provided by scanning tools facilitates educated decision-making, leading to smoother control amongst various trades and stakeholders. This improved collaboration decreases problems, improves try these out productivity, and ultimately increases job shipment.

Furthermore, by proactively dealing with issues via concrete scanning, construction teams can stick to routines a lot more effectively, decrease downtime, and optimize resource allowance. The ability to identify covert barriers and verify structural stability successfully adds to general job efficiency and timelines, guaranteeing successful results and customer fulfillment.

Ensuring Security and Danger Mitigation

Threat reduction methods can be boosted via the in-depth info given by concrete scanning, allowing project groups to make enlightened choices that decrease the chance of unexpected cases. In addition, by precisely drawing up subsurface conditions, service providers can avoid costly rework, hold-ups, and damage to existing structures, further adding to total task safety and security and success. Implementing concrete scanning as a routine practice not only makes certain a much safer workplace but likewise infuses confidence in stakeholders relating to the project's commitment to high quality and danger management.

High Quality Guarantee With Concrete Scanning

Concrete scanning plays a crucial role in upholding quality control standards within building jobs. By utilizing advanced scanning technologies such as Ground Passing Through Radar (GPR) and Concrete X-ray, job supervisors and designers can make sure the integrity and top quality of concrete frameworks. Via concrete scanning, possible flaws, such as spaces, cracks, or enhancing bar congestion, can be found non-destructively, permitting for timely interventions to preserve the architectural honesty of the task.

Quality assurance via concrete scanning not only helps in identifying existing problems however also makes it possible for proactive steps to prevent future problems that could why not look here compromise the security and durability of the framework. By carrying out thorough scans at essential phases of building and construction, groups can confirm the precision of structural strategies, validate the positioning of vital aspects, and attend to any discrepancies promptly. This positive approach lessens rework, decreases costly hold-ups, and inevitably leads to the distribution of top notch, long lasting frameworks that go beyond or meet industry standards.

Final Thought

To conclude, concrete scanning plays a critical role in making certain job success, top quality, safety, and efficiency guarantee. By utilizing sophisticated modern technology for specific outcomes, building and construction jobs can be finished with greater accuracy and within timelines. The critical side supplied by concrete scanning permits for proactive risk reduction and improves total project monitoring. Integrating concrete scanning into building processes is essential for achieving unrivaled success and ensuring quality results - RainierGPR Concrete Scanning.

In the world of modern-day construction and infrastructure growth, the application of concrete scanning technology has actually emerged as a crucial tool for making sure job success and preserving quality criteria. By incorporating these advanced innovations into concrete scanning methods, construction teams can simplify workflows, minimize task delays, and ensure the general quality and success of the project.Given the vital nature check my reference of task efficiency and timelines in building monitoring, the focus currently changes towards guaranteeing security and mitigating dangers within the job atmosphere.Concrete scanning plays a critical role in maintaining quality guarantee standards within construction projects. By utilizing innovative scanning modern technologies such as Ground Penetrating Radar (GPR) and Concrete X-ray, job supervisors and designers can ensure the stability and top quality of concrete structures.

Comments on “RainierGPR Concrete Scanning: Specialist Insights and Best Practices”